Nireas-IWRC Decennial Activity Report 2011-2021 March

High resolution

Low resolution

Το μυστικό βιβλίο του μπλε κύκλου

Το Διεθνές Ερευνητικό Κέντρο Νερού Νηρέας του Πανεπιστημίου Κύπρου και η Top Kinisis παρουσιάζουν ‘Το μυστικό βιβλίο του μπλε κύκλου’ απο τις ΕΚΔΟΣΕΙΣ ΠΑΠΑΔΟΠΟΥΛΟΣ.

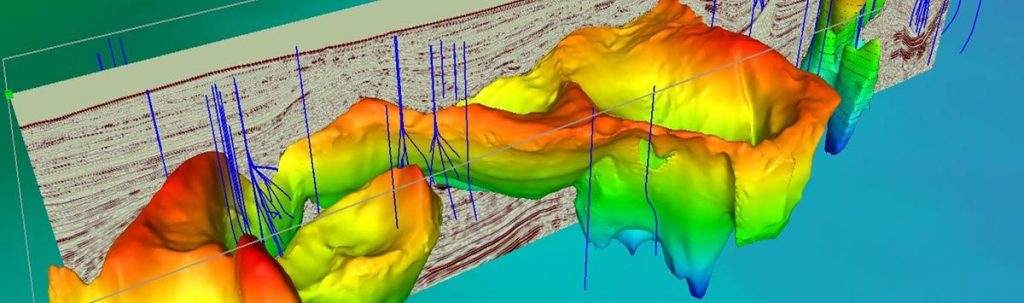

Research Pillars

Nireas-IWRC’s research activities are founded on seven equally important pillars.

Outreach Activities

Σημαντική χρήση μεθαμφεταμίνης στην Κύπρο τα τελευταία χρόνια, σύμφωνα με Πανευρωπαϊκή Έρευνα – 20/03/24

Σημαντική χρήση μεθαμφεταμίνης στην Κύπρο, αλλά χαμηλότερα Eυρωπαϊκό μέσο όρο για άλλες ουσίες. Πανευρωπαϊκή Έρευνα …

World Water Day – 22 March 2024

Economic, social and environmental prosperity of communities and protection of public health, food and energy systems …

Job Announcement at GAIA Laboratory – Deadline 10/03/24

A new part-time job announcement by Gaia, Laboratory of Environmental and Engineered Water Processes and Systems …

Kick-off meeting of the LESLIE project at UPV – 27-28 of February 2024

On the 27 and 28 of February 2024 the kick-off meeting of our project LESLIE (Land …